6 Aug 2025 - 2.5 hours

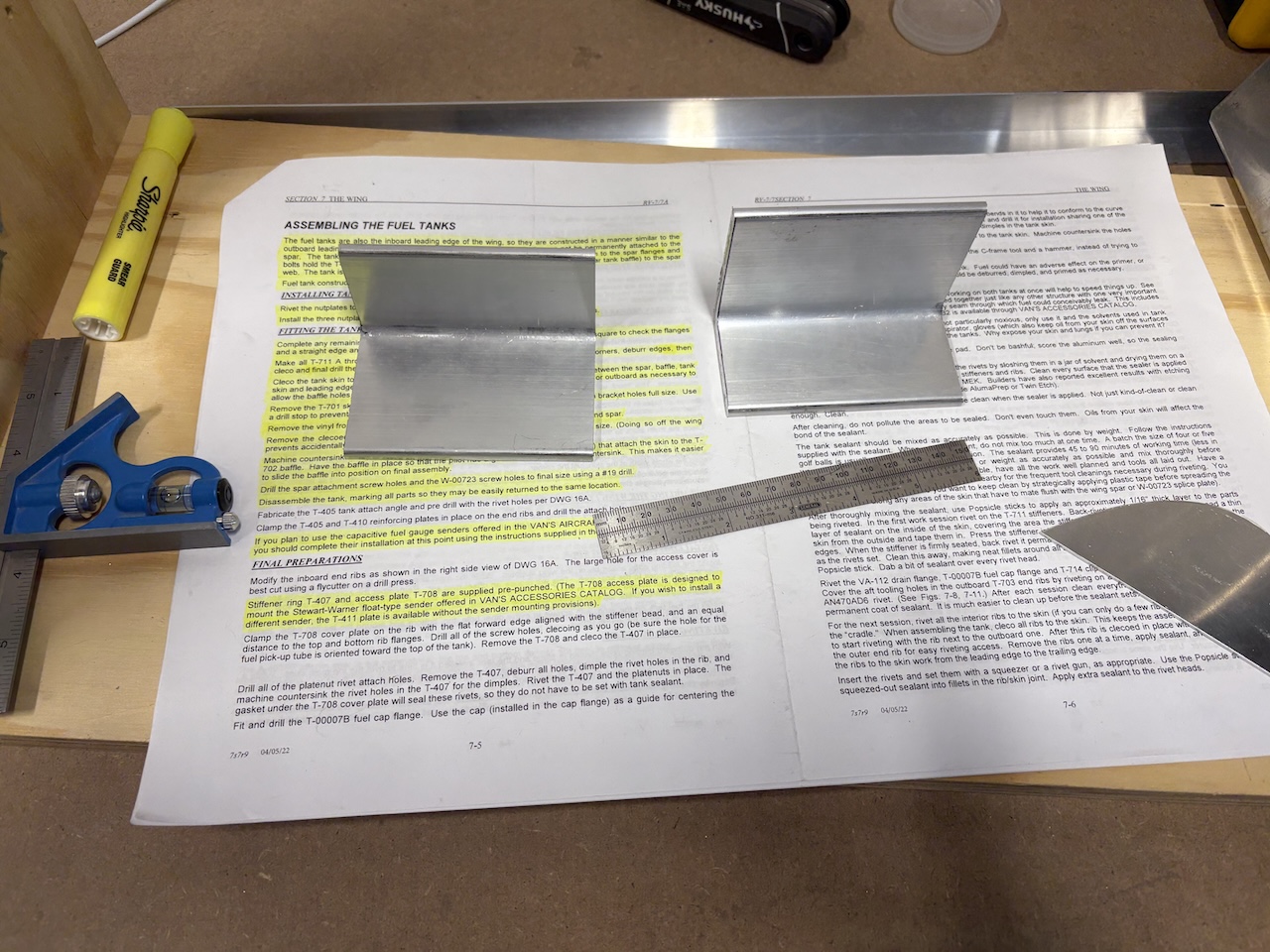

Back to work on the plane after quite a few days. I disassembled the tanks and got all the parts marked so they could go back in the same position when we get to that bridge. Then I started on the bits and bobs that go on the inboard and outboard tank ribs. I cut apart and deburred the nose doubler pieces as well as the tank inspection hole panel and nutplate reinforcement ring.Then I started marking and cutting to make the T-405 tank attach brackets. These are made from beefy 2x2.5" aluminum angle that is 3/16" thick. There are some vague measurements in the plans and then you take some artistic liberties to make them look about right... Here I've cut the big piece of angle into smaller pieces that will become by tank attach brackets.

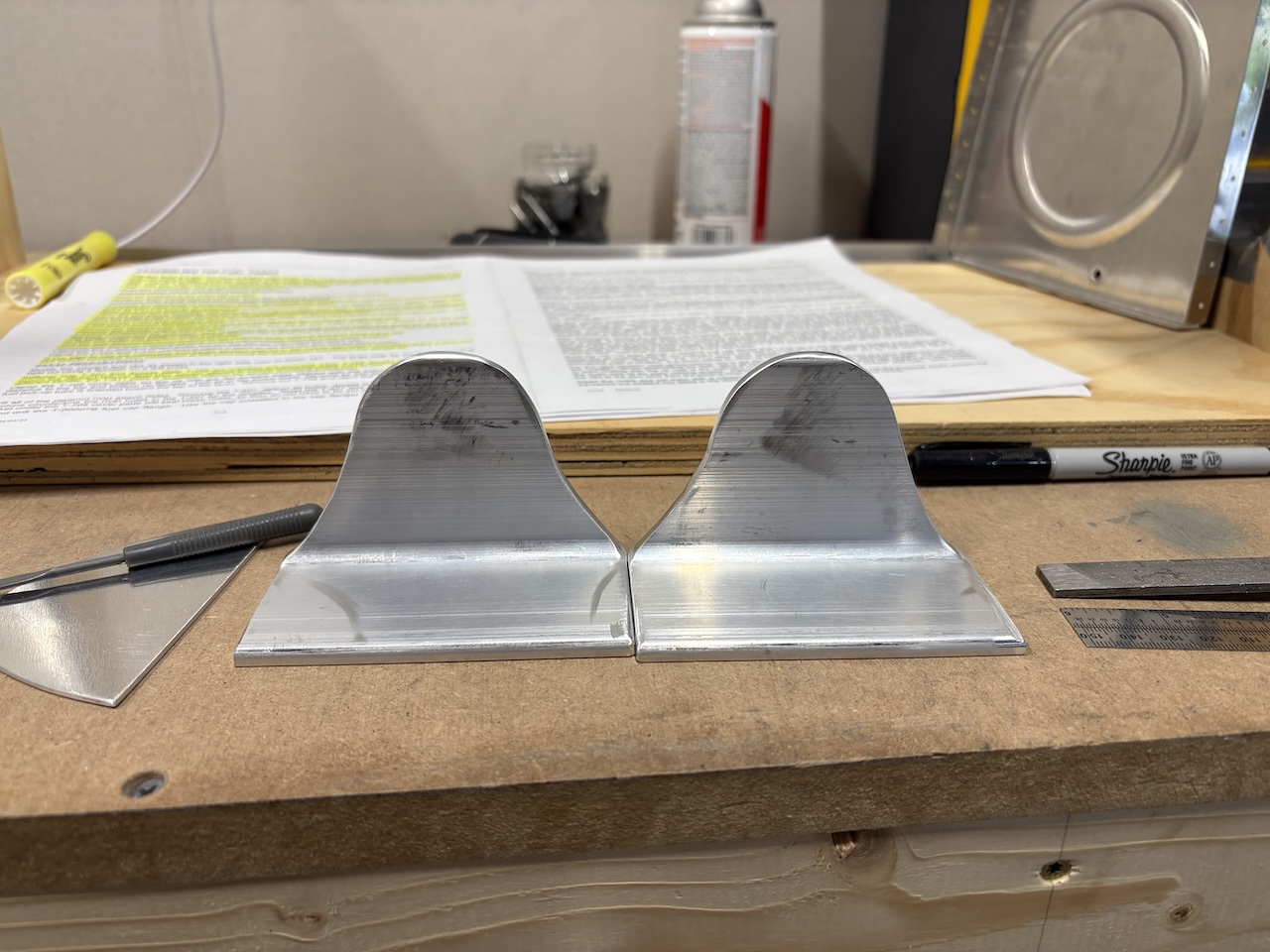

Then I plotted out a shape that met the dimensions given in the plans and looked like the drawing where there were no dimensions.

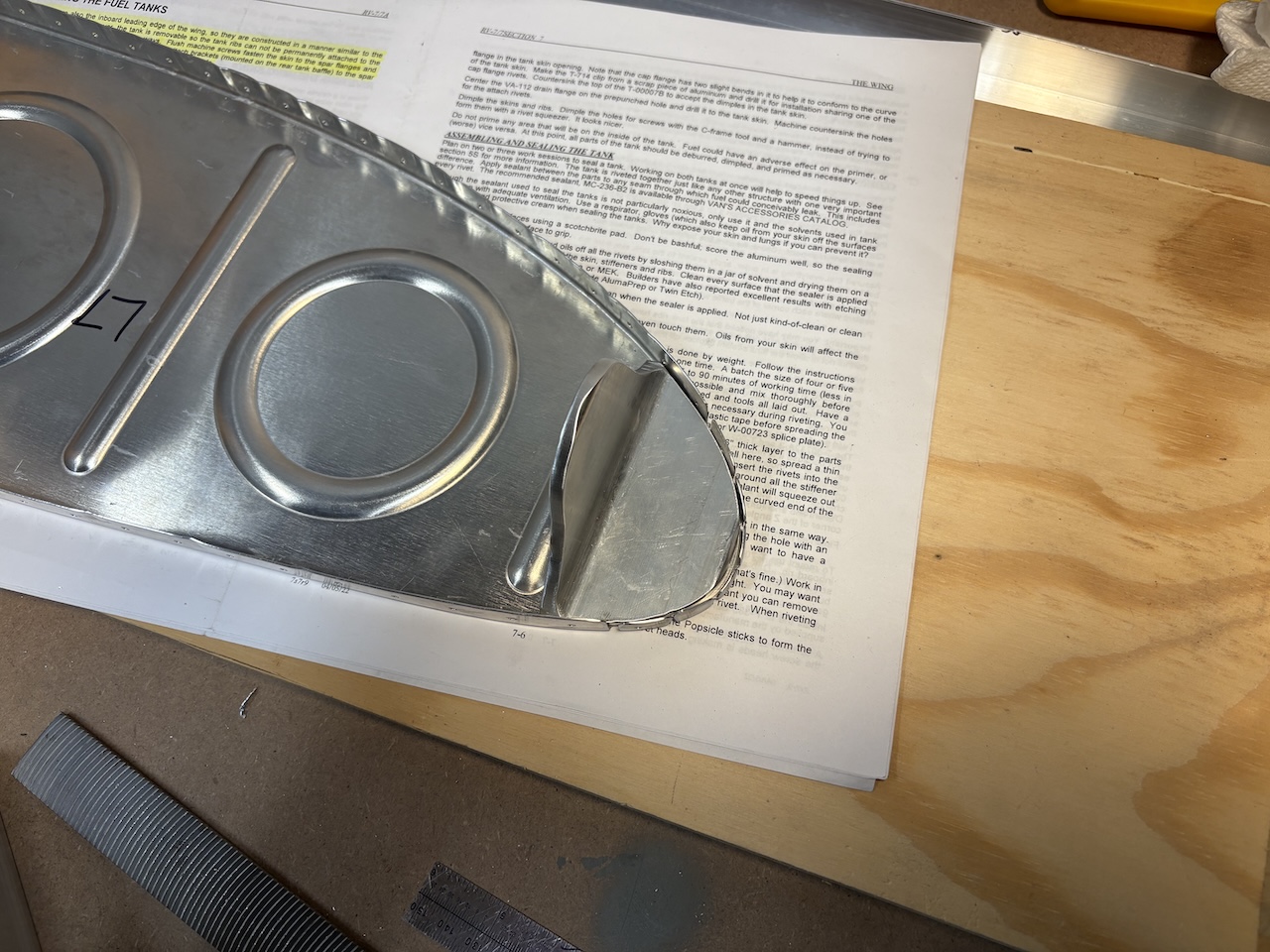

Using the doubler piece that these will mate with, I traced out the leading edge of the nose shape onto the back of the bracket. I cut these at the bandsaw and used a block of wood to prop the brackets up so I could cut them with the outside facing up (because that's where I was able to draw my line to cut to...). Here is the first one sitting in it's tank rib.

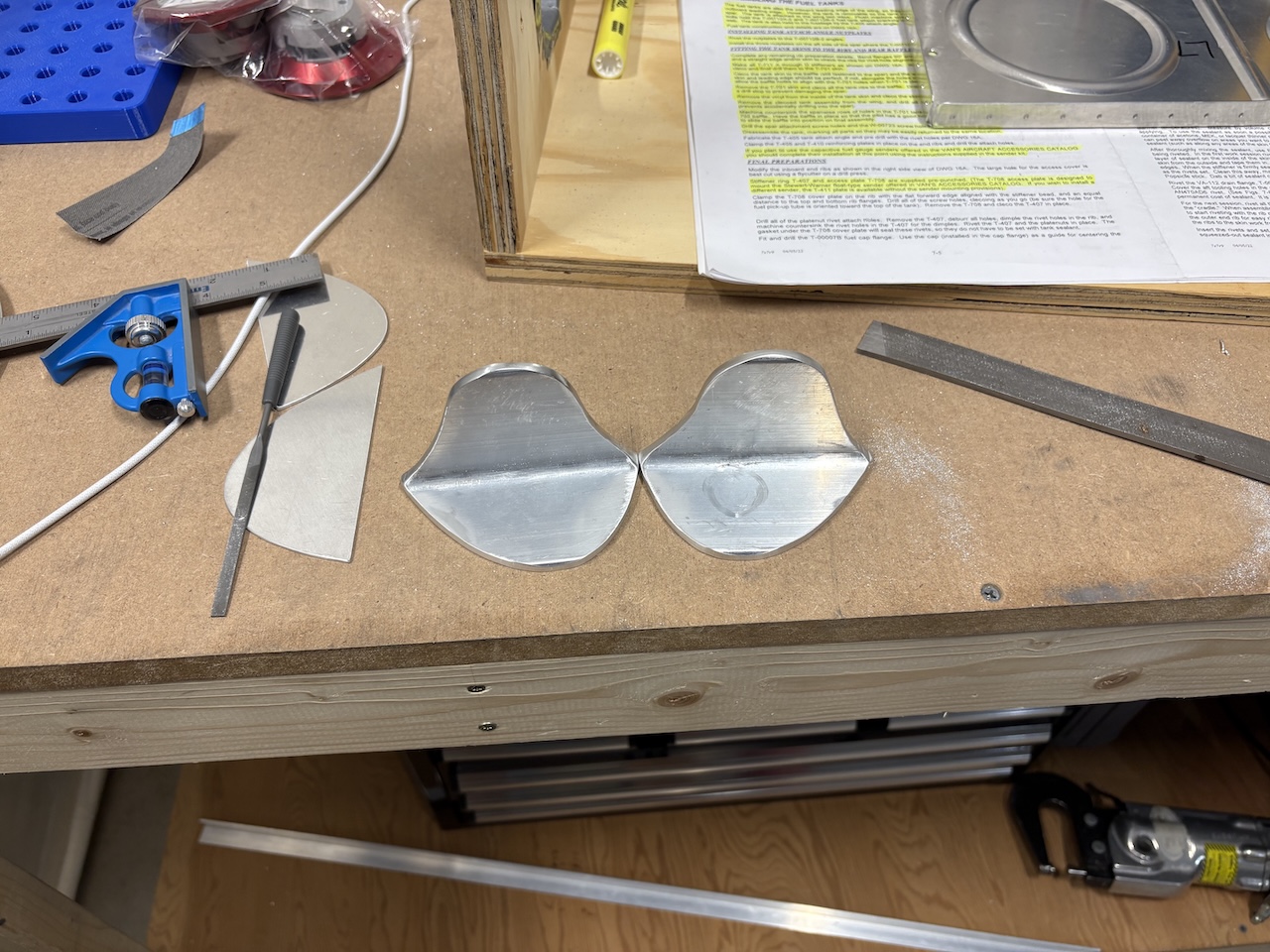

I used the first one as a pattern for the second one, making sure to make a mirror image of the nose rib shape so that I had a left and a right.

These are a lot of work but the grunt work on these bad boys is behind me! Next will be some hole drilling and then cutting a giant hole in the inside tank ribs!