23 Jun 2025 - 1.5 hours

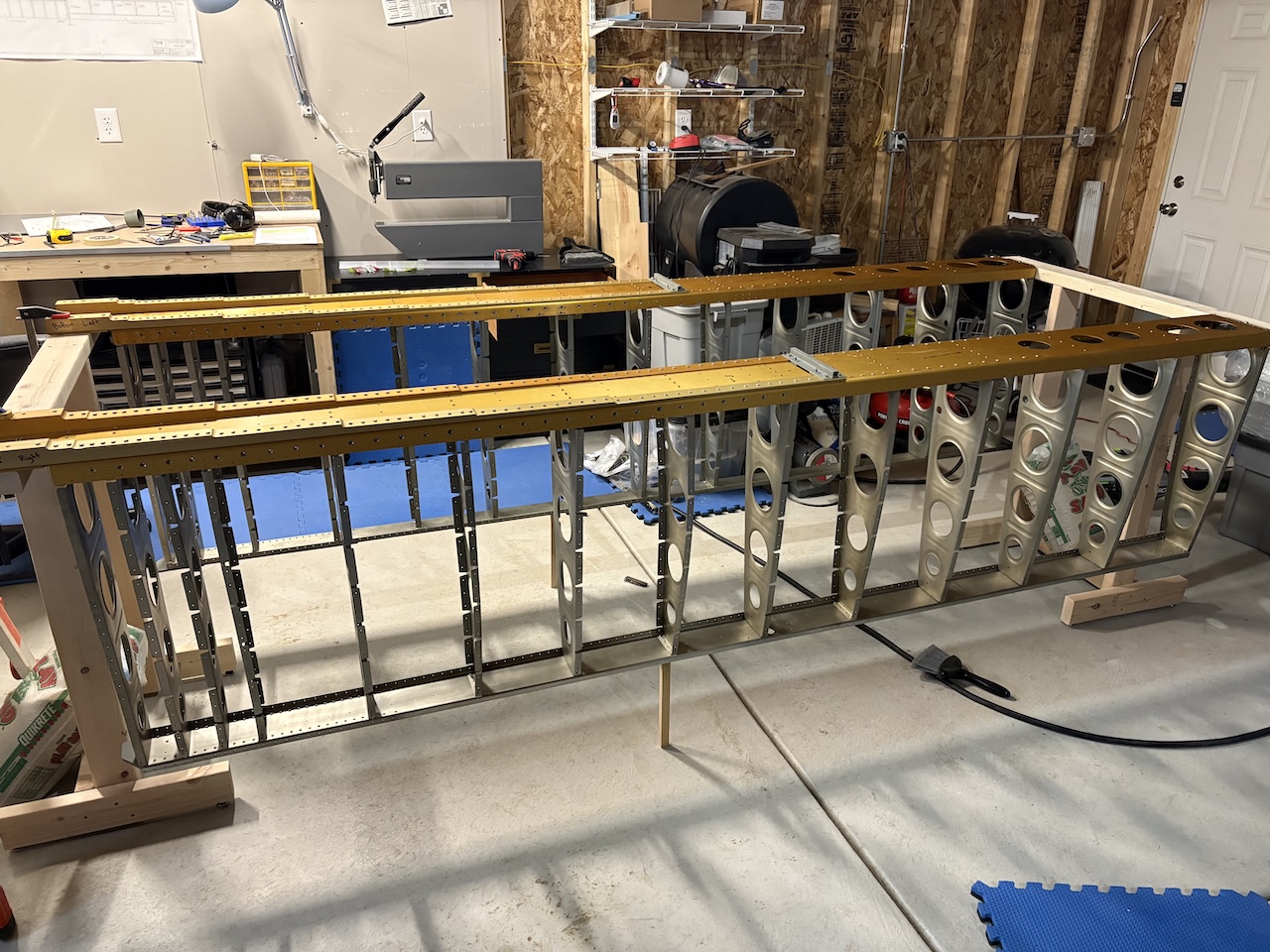

Now that I have some assemblies that look like giant airplane parts, it's time to make someplace to hang them. The plans and instructions give an example of what to build as a stand for the wings. They don't need a precision jig to ensure that they are straight because of the pre-drilled holes. That means the stands just need to hold the wings during the build process and be reasonably plumb and level.I couldn't/didn't want to do the 4x4 posts from floor to ceiling because my garage doesn't have a ceiling and I didn't want to drill into the floor so I went with 2x4 stands. They are 36" tall and the gap between the uprights on the stands is 20". It's wide enough that you can climb through and work from between the wings which end up being about 24" apart.

I made one stand about 1.5" taller to account for the slope in the garage floor. I also used adjustable feet so that I could level them out nicely and eliminate the wobble. A laser level allowed me to get both stands level and in-plane with each other. I also cut some sticks to prop up the middle of the rear spar to help eliminate sagging.

I mounted the outboard tip with two #10 machine screws, washers, and nuts through a 5" long 1"x1"x1/16" piece of aluminum angle. I will need to notch a bit of the stands where the skins hanging over the outboard edge will interfere a bit.