16 Nov 2025 - 4 hours

Things went very similar to yesterday, only this time with the outboard ribs. I sealed and installed the rib first, then added the nose doubler and tank attach bracket to the nose of the ribs. They had to go in second because they would block access to setting rivets if they were installed first.

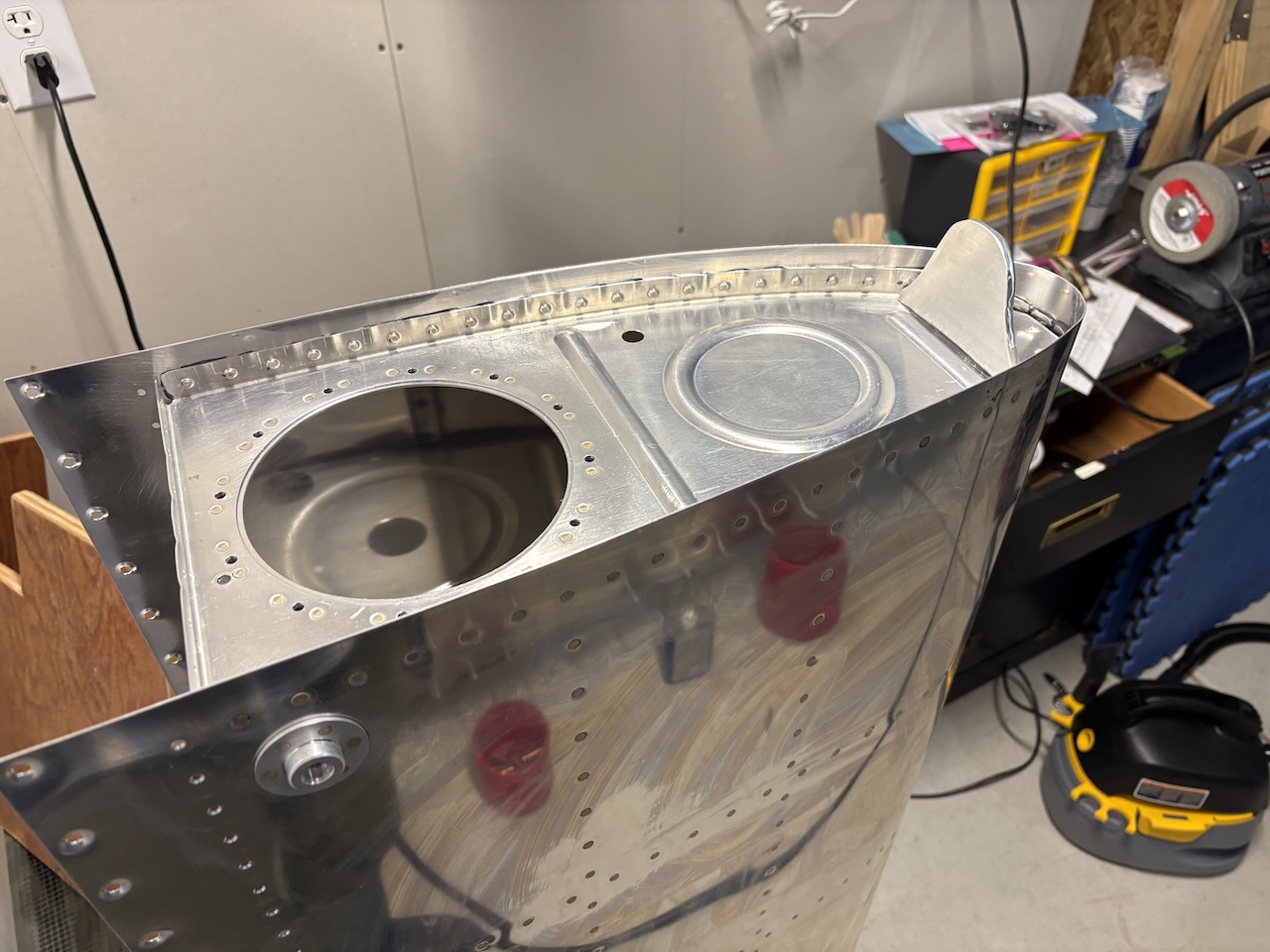

At the end of today, I went back and added a bunch of sealant in the gap between the attach bracket and the skin. There are big holes there in the ribs to accommodate the tight bends in the forming process so I figured extra sealant can't hurt.

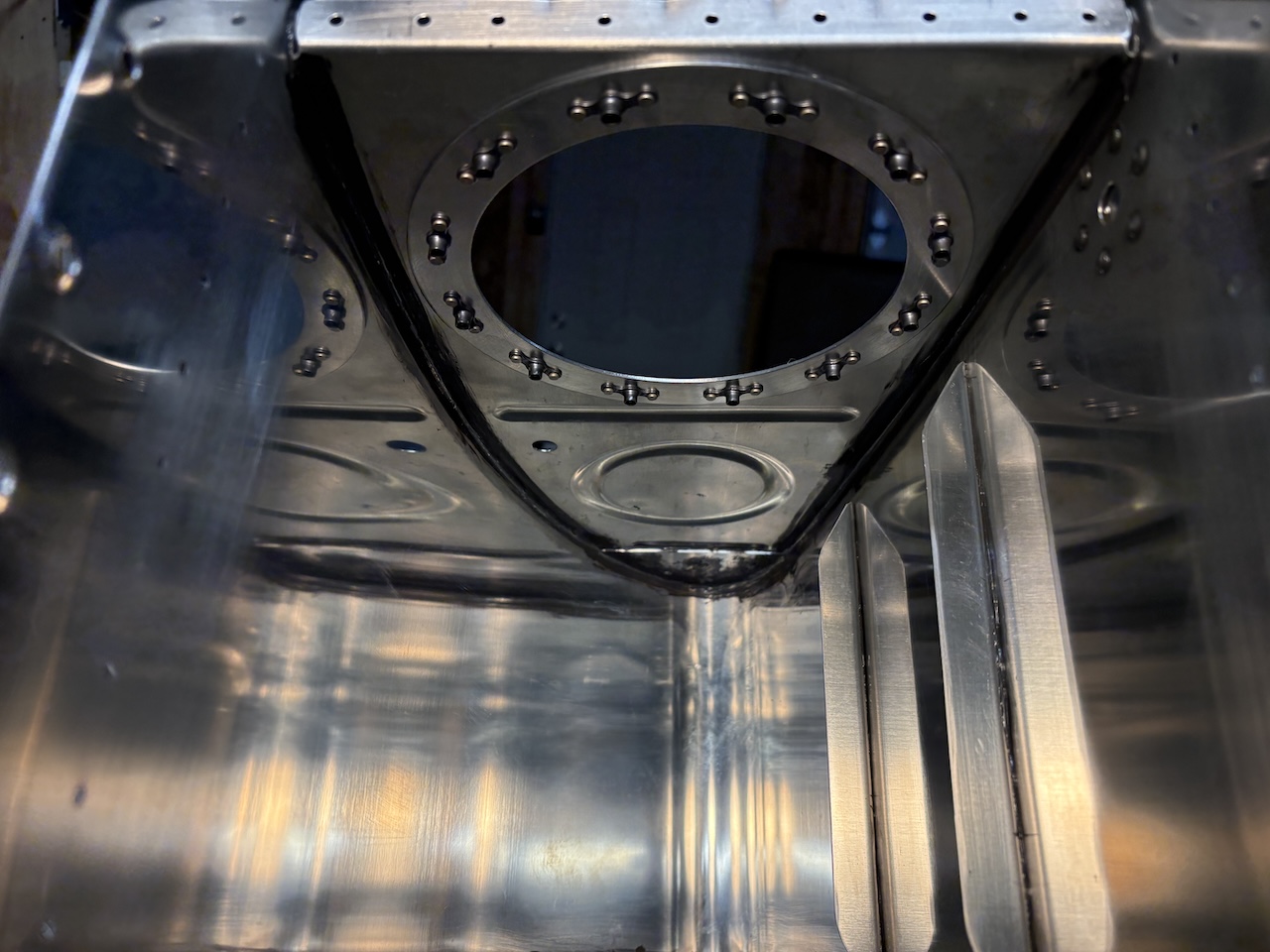

Here is the inside. I feel pretty dumb for trying to fillet the gaps using a popsicle stick because just using my finger worked so much better and was much easier, cleaner, and quicker. I was worried it would make a huge mess to use my finger but once there was a little sealant on the glove finger tip, it didn't pick up any more and smoothed things out very nicely. I might even go back over all the other seams inside the tank where ribs meet skin and put in a fresh bead of sealant and smooth it out with my finger, just to be sure there aren't any leaks.

The end of the tanks is in sight and I am fired up about that. Have a few fiddly bits to install like the fuel pickup, fuel float, vent line, and close off that big hole, then they get closed out with the baffles!