11 Jan 2026 - 0.5 hours

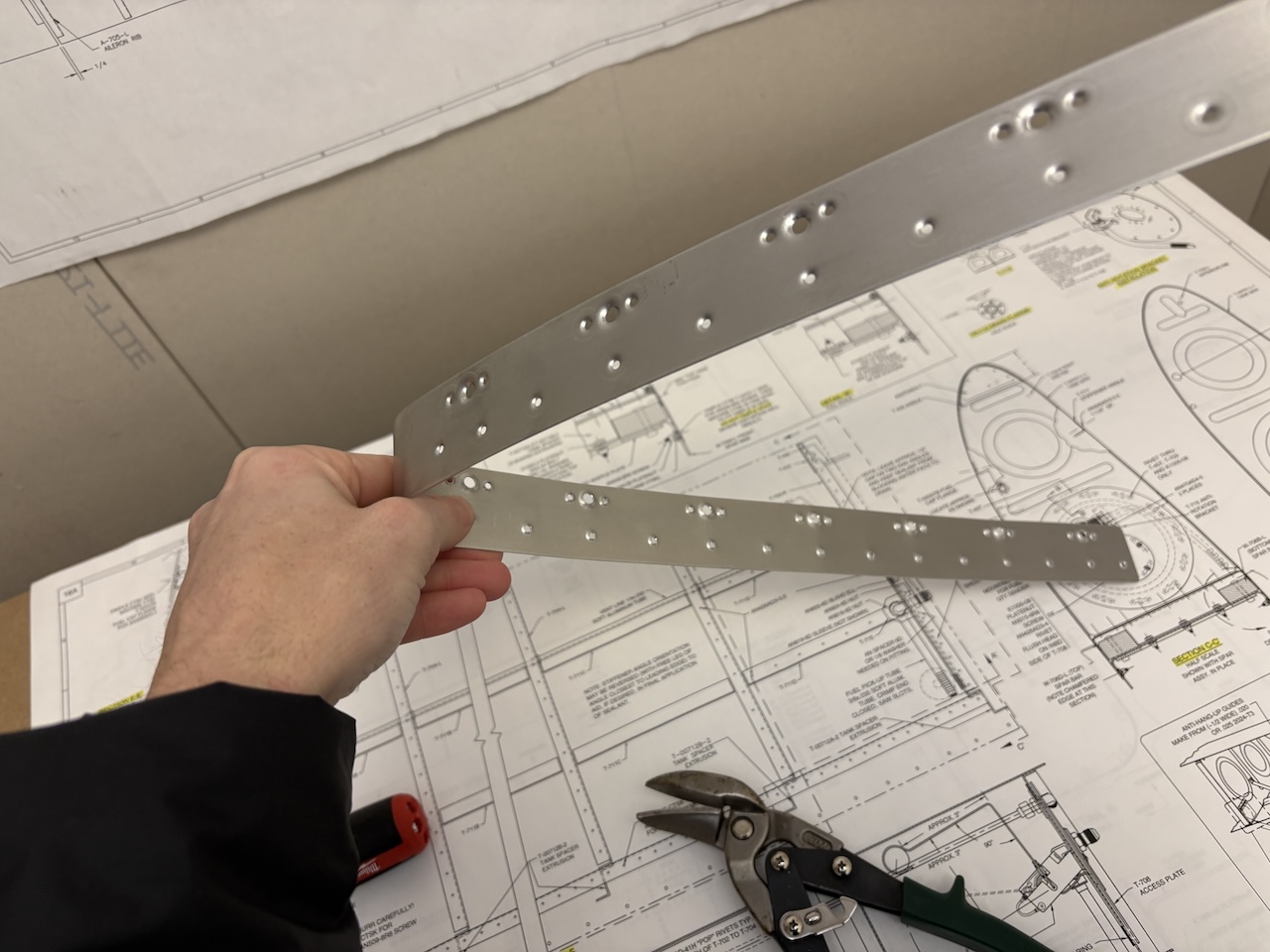

I mixed it up a bit from deburring wings parts and switched over to dimpling the tank to leading edge splice plate. The outboard edge of the tank screws into this strip where it meets the leading edge's inboard edge. Easy dimpling on the rivet holes and screw holes.

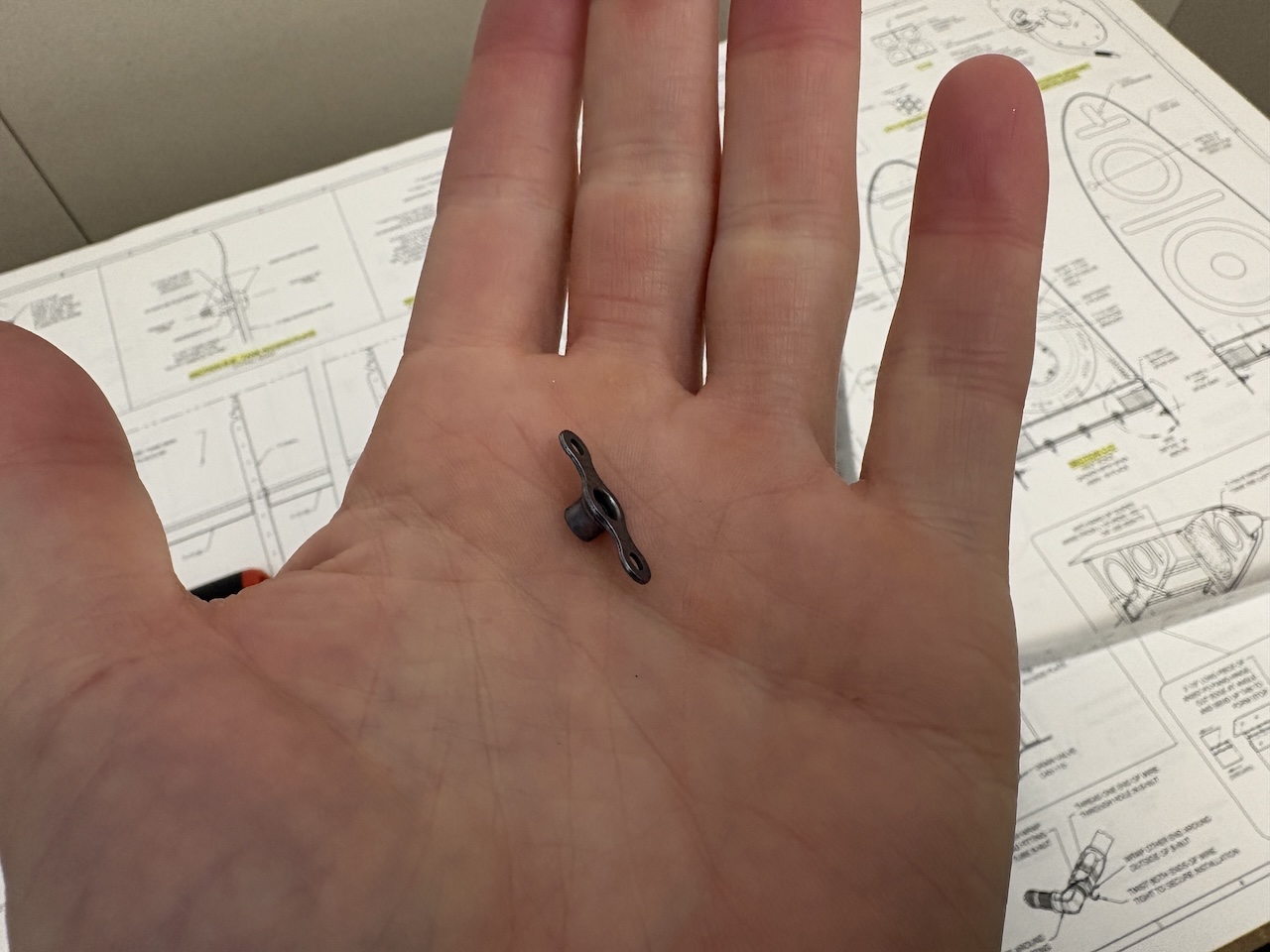

Then things went pear shaped. I was doing a test fit with a K1100-08 nutplate that goes on the splice plate and noticed they were not countersunk, so the screw dimples had no where to nest. It turns out that bag 1922-1 is supposed to have 210 K1100-08 countersunk nutplates but mine, in fact, had 210 K1000-08 non-countersunk nutplates. Normally, this wouldn't be a huge deal as I haven't put the wrong nutplates on anything yet. Except I have. I put 120 of these on the spars for the tank trailing edge attach screws.

When putting these on the spars, it seemed correct as the spar is countersunk so the non-countersunk nutplate which sits flush against the flat backside of the spar made sense. I guess it needs to be countersunk though as the dimple from the skin is deeper than the depth of the spar flange so it will extend down into the nutplate countersink, hence those should actually be countersunk nutplates...

I have a support email into Vans to see what the way ahead is.