1 Feb 2023 - 1.8 hours

I still haven't sorted out priming so I am moving on to the next assembly, which is the rudder.The rudder is made from very thin skins that meet at a knife edge on the trailing edge so there isn't room inside the part for a skeleton of ribs and spars like for the stabilizers. The thin skins need support which comes from stiffeners that run from leading to trailing edge and give them strength.

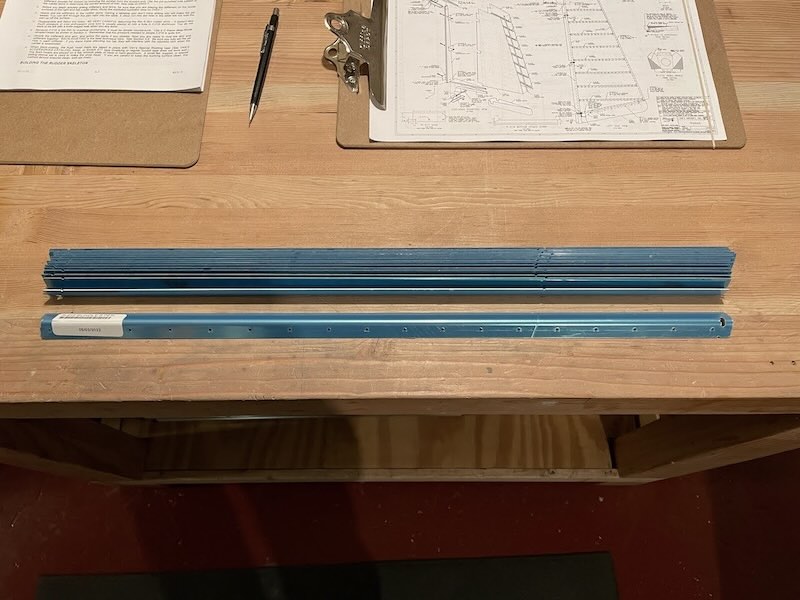

The 16 stiffeners come in aluminum angle with two per piece, which need to be separated and trimmed to size. Here are the stiffeners as received.

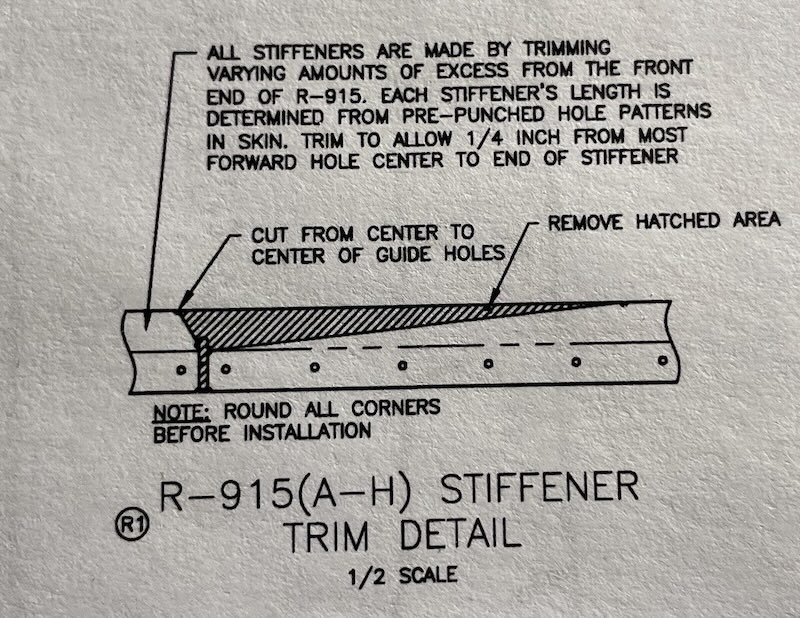

They have pre-punched holes indicating how to trim the ends to length. The trailing edge gets trimmed down fairly significantly so that they fit between the skins as they narrow towards the trailing edge.

First, I cut the pieces in half to separate the two stiffeners that were in each piece.

Then, I trimmed the trailing edge of each of the 16 stiffeners. I used the snips to do this, starting at the marking hole on the flange and trimming down towards the marking hole right on the bend between the web and flange. This operation is a little awkward and it matters which set of snips you use (right vs left) as the snips will curl and deform the 'waste' side, which you want to make sure actually is the bit that will be discarded.

I only trimmed and smoothed all of the trailing edges tonight. The rudder narrows from bottom to top so the stiffeners are all different lengths. You find the length by using the prepunched holes in the skins and trimming the stiffener to reach 1/4" past the forward hole. Trimming the forward edge of the stiffeners and deburring them all will be the next step!