27 May 2024 - 5 hours

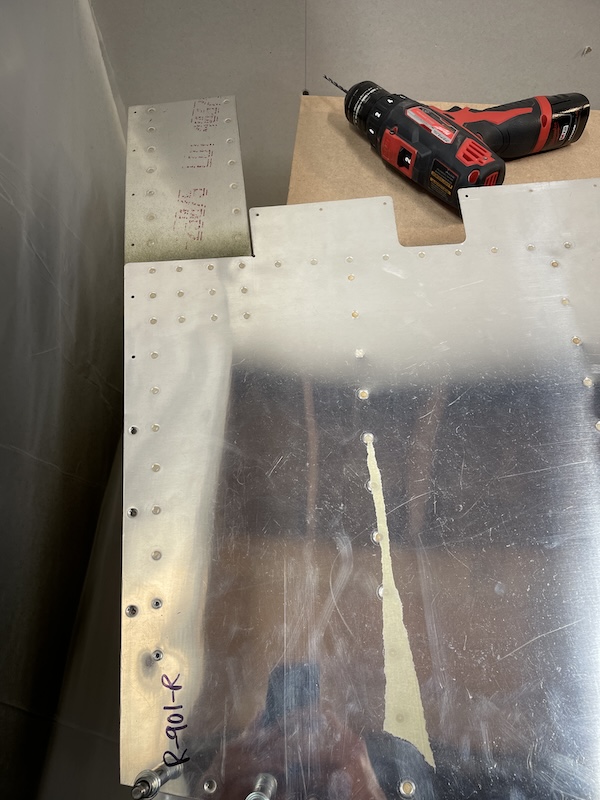

Made a lot of progress today as I was in and out of the garage on this Memorial Day off of work. I started by finishing the rudder spar doubler plates, including the K1000-6 nut plates.

I got the rudder horn and bottom rib all buttoned up. I was able to squeeze all of these rivets using the longeron yoke in the squeezer.

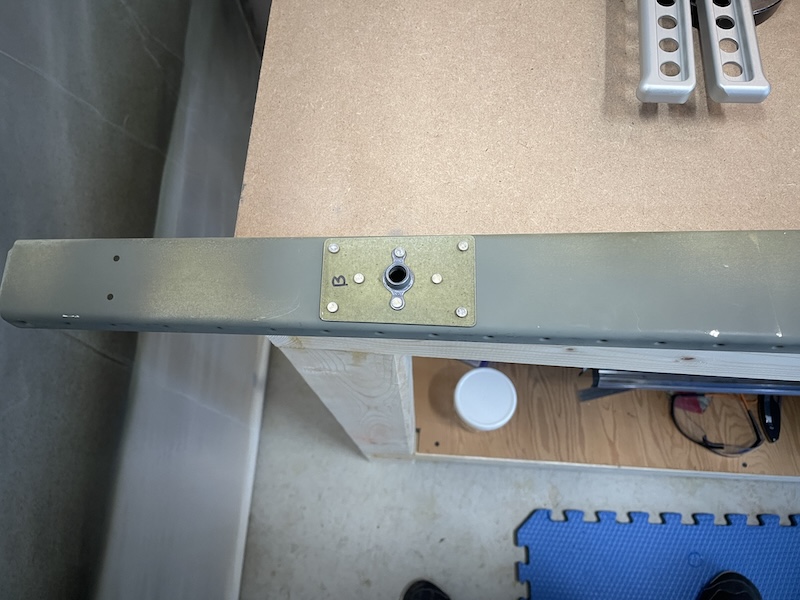

I took a picture of the middle plate before it gets closed up.

And the top plate.

I was able to get all these rivets inside this piece using the longeron yoke again. It worked great!

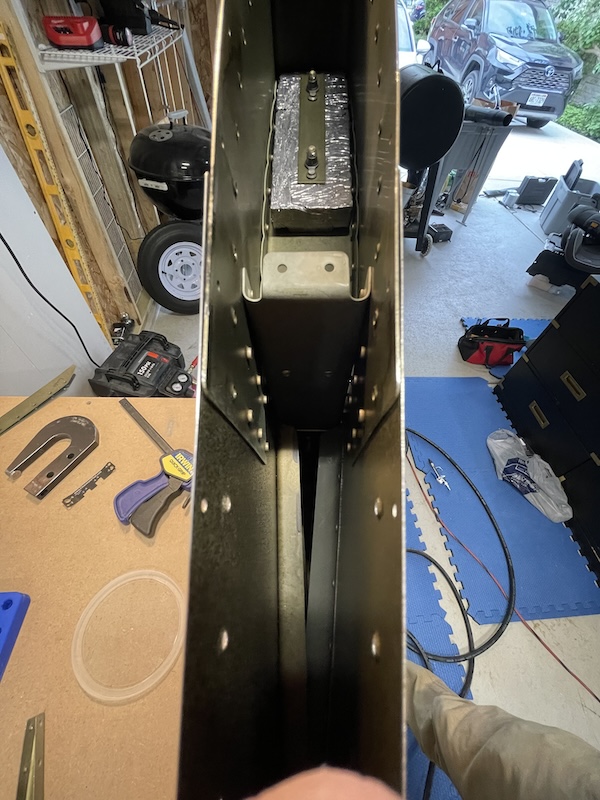

Once all the skeleton bits were riveted together, I put the counterweight in it's place (which required a bit of filing to get it to sit all the down past the rivet shop heads) and then riveted on the counterbalance skin. Here is inside the top of the rudder before I sealed it up with the tip rib.

Then it was just a matter of running around the edge of the rudder and squeezing all the rivets. The star of the game today was the different yokes: the longeron yoke and no-hole long-reach thin-nose yoke. The long reach let me get all the rivets inside the rudder and lower down on the spar where the skin overhang gets pretty long. With its thin nose, it also allowed me to squeeze pretty far down into the skinny bits, too.

I used one pop rivet in the aft-most hole on the bottom rib and I used two pop rivets in the aft-most two holes on the top rib.

I'm very pleased with how the rudder is turning out so far. I think the only thing left on it is to epoxy and rivet the trailing edge and then the rudder will be behind me (pun intended)!