31 May 2024 - 3.5 hours

The trailing edge was nice and straight after being epoxied and clamped to a straight piece of aluminum angle. It took about 45 minutes to clean up all the epoxy squeeze out. I used the #40 countersink in the deburring tool to clean the epoxy out of the dimples. I turned it by hand just enough to catch the epoxy and it chipped out mostly cleanly. This made sure the rivets would sit flush in the dimple.

I riveted the trailing edge by starting with the back-rivet set and set them all about half way, following the instructions. Then I flipped over the rudder and used a flat set drive home the rivets, again, as the instructions said. There was some ever-so-slight wave to the trailing edge so I did some gentle strategic taps with the rivet gun to straighten it back out.

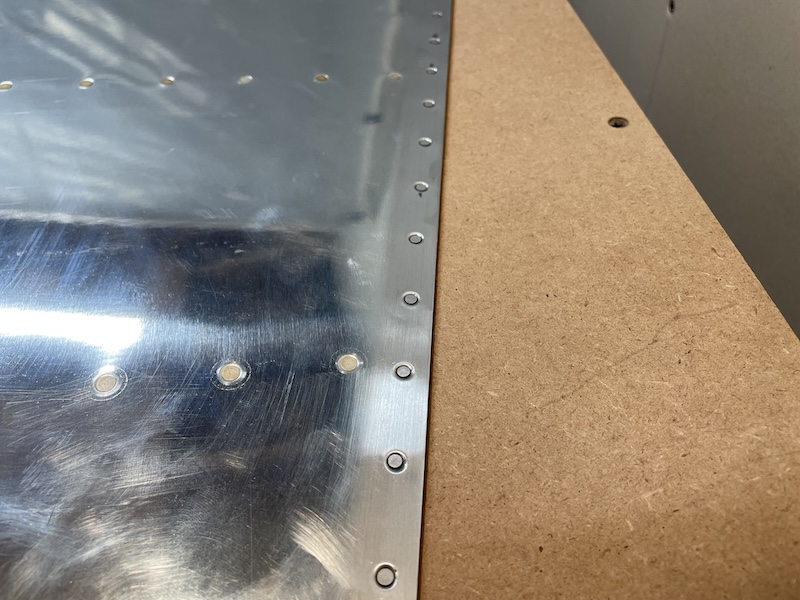

The shop heads came out nice.

As did the manufactured heads.

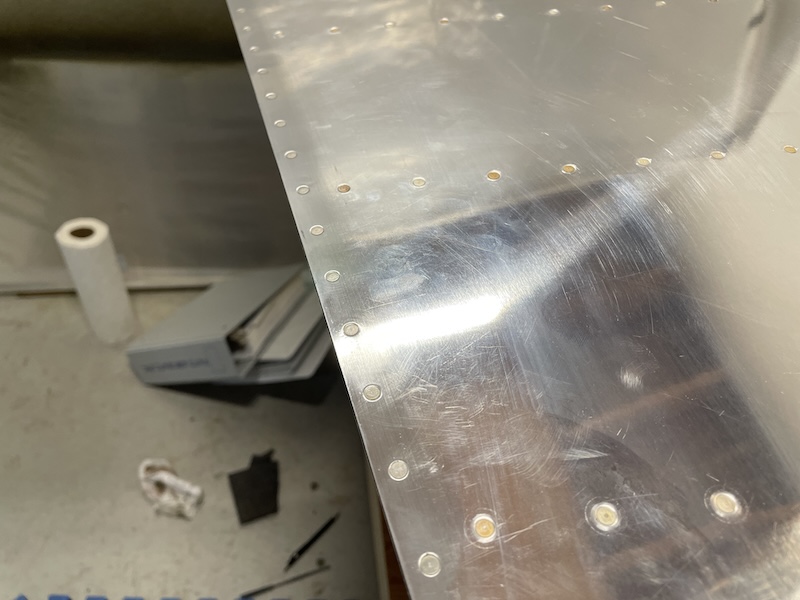

All the rivets set!

Next I moved onto rolling the leading edge which is still a huge pain. Eventually, though, I got it done and it looks pretty good!

After drilling and deburring the leading edge rivet holes, I set all the leading edge pop rivets.

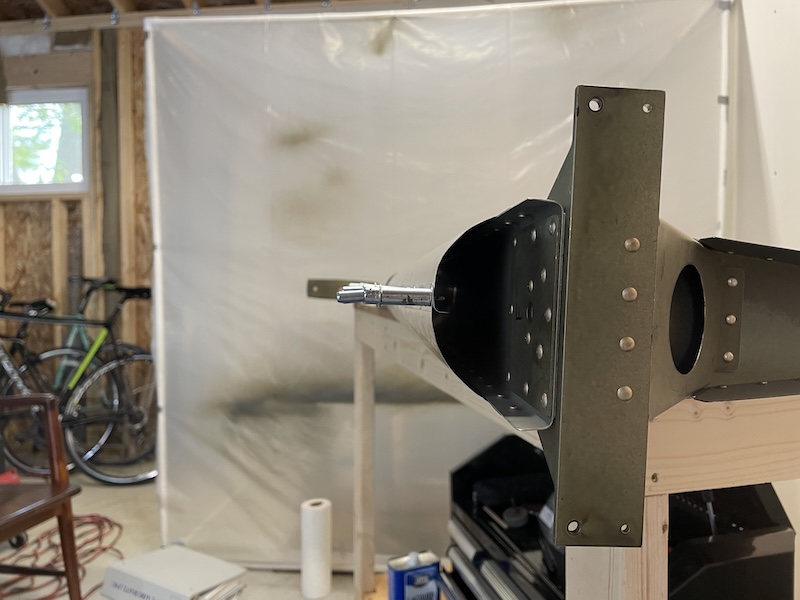

And with that, the rudder is done!